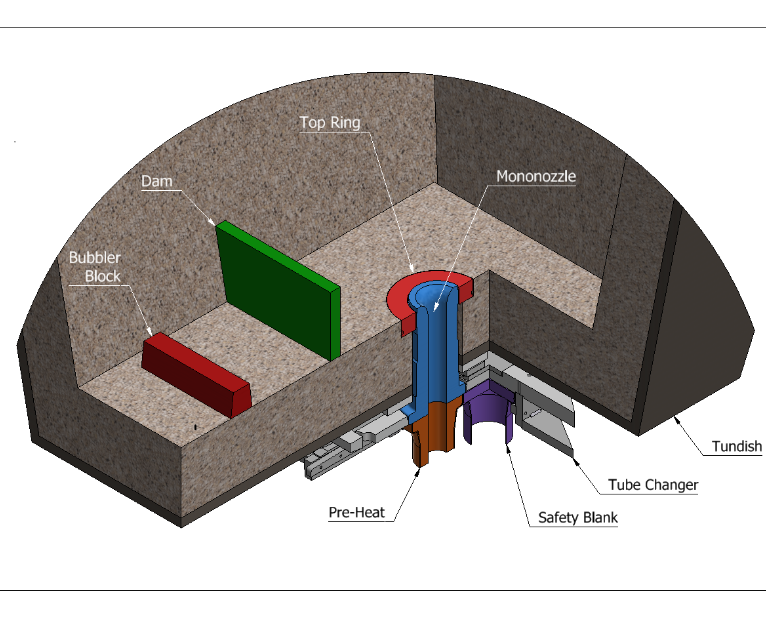

Mononozzle

A combination of tundish nozzle and sliding-gate-type stationary plate as one item, through which steel pours from tundish to mould, and the sliding surface of which facilitates the tube change. All mononozzles have argon protection to the sliding surface and the majority have argon supply to the stopper seating area, although “solid” nozzles are available for use with e.g. CaSi treated steels if necessary.

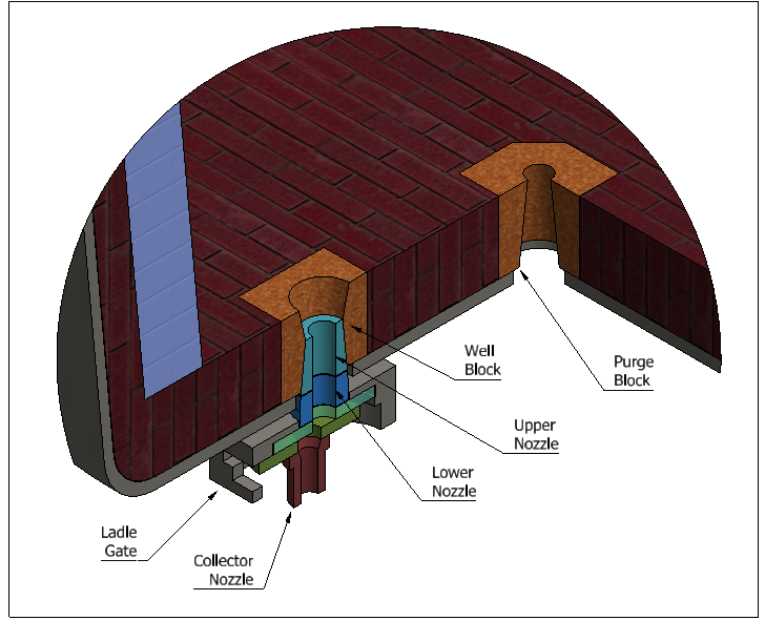

Bubbler Housing & Well Blocks

High wear-resistant pre-cast product that manages localised turbulence and maintains uniform dimensional control, enabling seating of the purge plug.

Schematics Showing Typical Setup Of Tundish & Ladle

Website Built & Powered By SK Web Design